Recent news around Ørsted’s announcement to cease development of its two US offshore wind projects Ocean Wind 1 and 2 have seen vessel shortages become the patsy.

Since early 2023 it has been no secret that Ørsted’s US projects would cost more than the company had anticipated and that increasing costs for vessels was one of the factors in that. However, it has now been said that vessel shortages were the blow that killed Ocean Wind 1 and 2. Given that Ocean Wind 1 has resulted in multi-billion dollar of impairments, this is some blame to lay on vessel shortages. I will admit that good installation vessels are short in supply, but I also believe that at one point the Ocean Wind projects had the vessel required to install foundations and turbines. Any delay in the timeline would be because of a potential loss of a vessel due to conflicting contracts, supply chain problems in general rather than a vessel shortage.

Ørsted was ambitious with its US pipeline. The company expected to execute back-to-back installations for South Fork, Revolution Wind, Sunrise Wind. Ocean Wind 1 was to be installed in parallel with Revolution Wind and Sunrise Wind. We are talking about 261 of the largest scale turbines being installed and COD between the end of 2023 and 2025 in a market that has not yet commissioned its first large scale offshore wind project and is required to feed the vessels with barges. Even in Europe this would be tricky, and the European supply chain is more experienced and the loading crew at the marshalling ports is well trained.

Efficiency in marshalling is key to avoid any delays on a project. For the Taiwanese offshore wind project Greater Changhua 1 & 2A the appropriate reason for the delay should rather be pointed at inefficient marshalling then a vessel shortage. The turbine installation vessel at Greater Changhua 1 & 2A was meant to finish the job before going back to Europe for its next contract. However, due to difficulties in load out in the port the vessel had long durations in port. In addition, the vessel’s carrying capacity was not fully utilized for each cycle. Due to conflicting contracts the vessel left the project unfinished. At this point vessel shortage become a problem as there was now a lack of availability for vessel in the region. Like the US, Taiwan is still in an immature state when it comes to offshore wind. This had an effect on the efficiency of the installation progress at Greater Changhua 1 & 2A. Lack of efficiency in marshalling is a common issue in immature markets, like Taiwan and US. Nevertheless, Greater Changhua 1 & 2A has had a total of 3 vessels installing turbines and will soon finish.

It can’t be denied that a vessel shortage has been part of the problem when it comes to Ocean Wind 1 and 2 and Greater Changhua 1 & 2A, but vessel shortage is not the only reason.

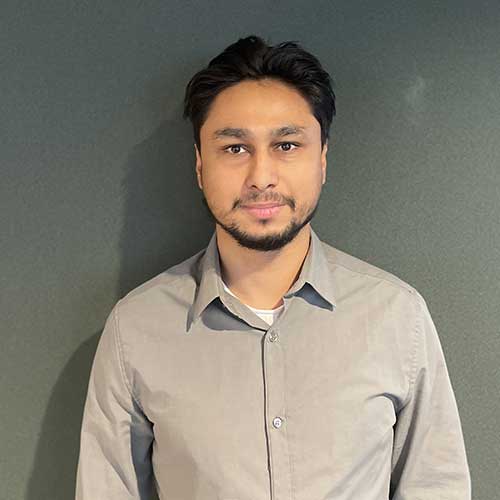

Image Credit: Vineyard Wind